OUR ENERGY AT THE SERVICE OF YOURS

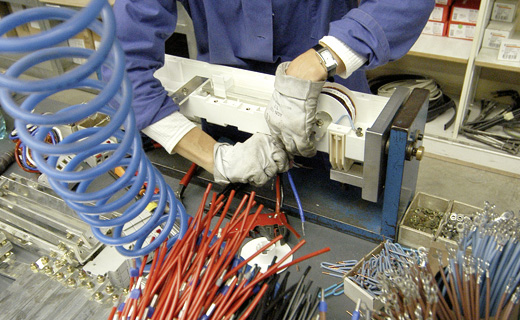

Since 1920, DEPAGNE has been manufacturing low-voltage electrical distribution equipment in Isère (France – 38). Certified quality AFAQ/ ISO 9001 version 2015.

The company has become a European market leader in port terminals. It has also been a reference for more than 50 years on the French market for lighting and candelabra connections. Through QSE management, DEPAGNE has for several years integrated Safety and Environment into its quality system.

In 2022, DEPAGNE employs 160 people on 3 sites. Very active internationally, DEPAGNE has had a particularly strong presence on the African continent for more than 30 years.

Driving innovation, its R&D department has a dual role: to imagine the applications of tomorrow and the products that meet the specific demands of its customers. Thanks to its testing laboratory, the department is responsible for ensuring that products comply with the standards and certification requirements.

OUR ENERGY SERVING YOURS

3

SITES

4.000.000

FINISHED PRODUCTS PER YEAR

100

YEARS OF EXPERIENCE

100%

DESIGNED AND PRODUCED IN FRANCE

TEAMS AND SKILLS

Our sales department advises our customers in the definition of their specifications and in the specification of their needs. Our 8 representatives canvass the national territory and build a close partnership relationship.

DEPAGNE, a specialist in the manufacture of counting and security boxes, today offers African Energy Companies a wide range of boxes for electronic meters and prepayment, in compliance with each of their specifications.

Thanks to its flexibility, DEPAGNE also carries out customized studies to best meet its customers’ specifications.

Our R&D department consists of a design office equipped with powerful CAD/CAD tools.

Our sales department advises our customers in the definition of their specifications and in the specification of their needs. Our 15 representatives canvass the national territory and build a close partnership relationship.

DEPAGNE, a specialist in the manufacture of counting and security boxes, today offers African Energy Companies a wide range of boxes for electronic meters and prepayment, in compliance with each of their specifications.

Thanks to its flexibility, DEPAGNE also carries out customized studies to best meet its customers’ specifications.

Our R&D department consists of a design office equipped with powerful CAD/CAD tools.